Motivation

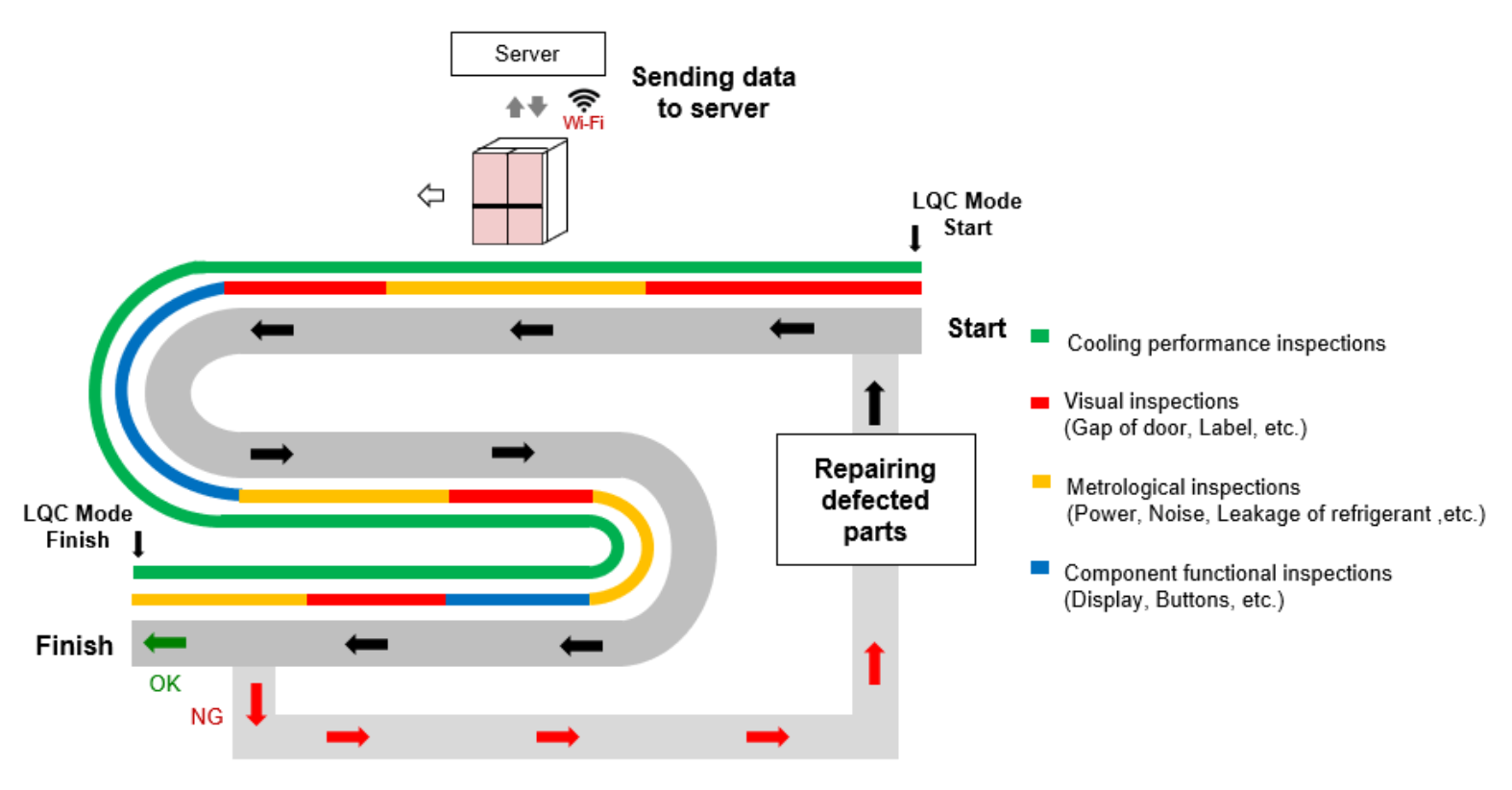

Defective products that are not detected during the LQC process are shipped to customers and later returned due to quality issues.

Methodology

Based on domain knowledge, the conditions of abnormal patterns are specified, and these are used to refine the training data for the model. A self-supervised learning methodology is employed, taking into account data contamination issues and the extremely limited information on minor defects.

Contribution

Before data refinement, defective products were rarely detected; after refinement, more than 80% of them were identified. The model also learned to distinguish abnormal data from normal data more effectively.