Motivation

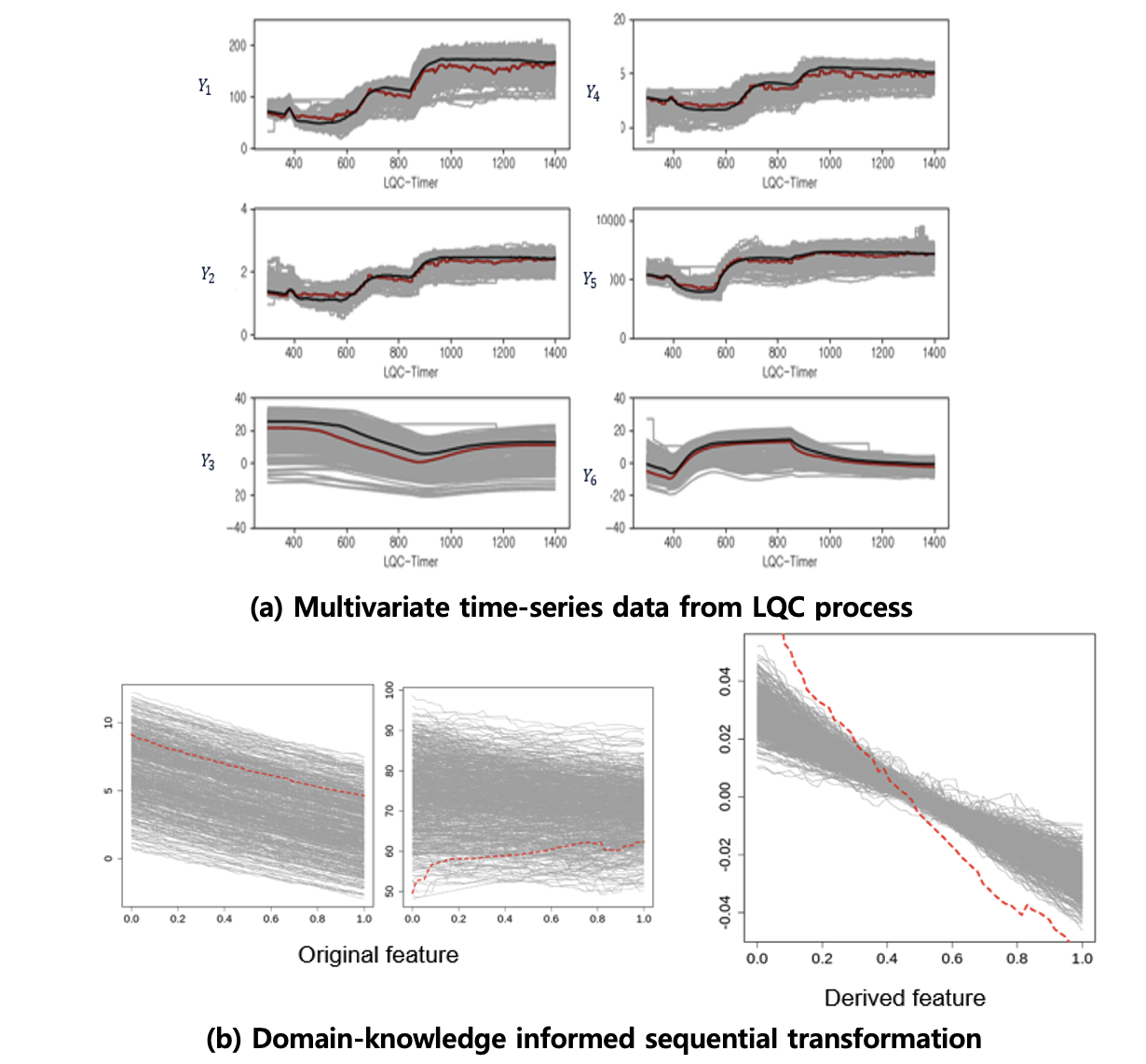

- In the manufacturing process, time-series data are collected from multi-sensors and used for quality control.

- In the line quality control system (LQC) process, weak failures that are difficult to detect with conventional detection methods occur.

Goal

- To develop a methodology for detecting tiny anomaly patterns in manufacturing time-series data using Sequential Transformation (ST) and domain knowledge of failure patterns.

Methodology

- The ST maximizes the time-series pattern of a tiny anomaly sample through various calculation.

- We utilize domain knowledge of failure patterns to define new derivatives and combine them with ST to improve their performance.